INDUSTRIAL BAKERY EQUIPMENT

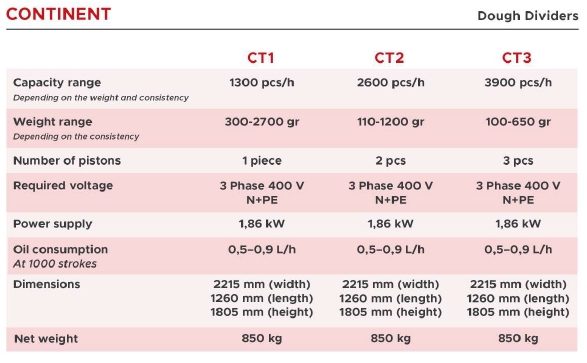

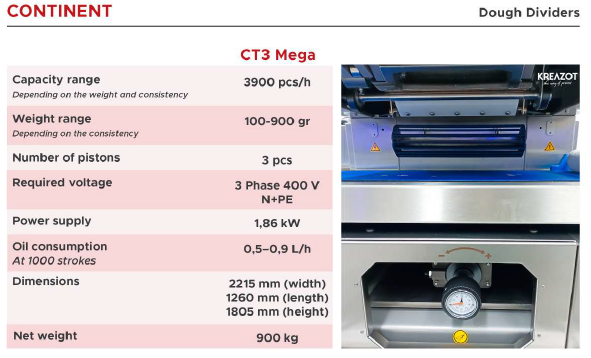

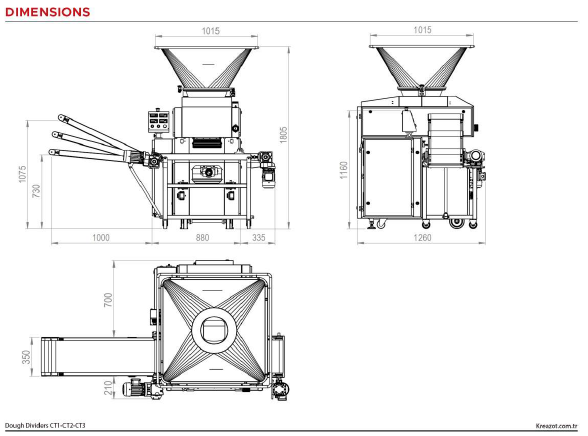

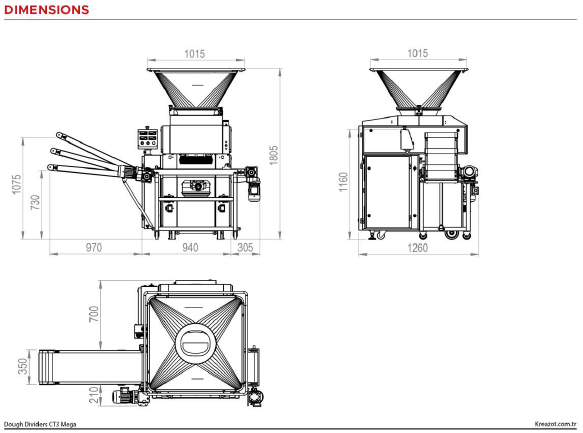

CONTINENT Dough Dividers – CT1 / CT2 / CT3 and CT3 MEGA

A highly precise dough divider with a proven long lifespan. Designed for versatility, it accommodates nearly any type of dough in almost any bakery setting.

Continent Dough Dividers – Precision & Reliability

The Continent Dough Dividers deliver exceptional accuracy

and durability, ensuring consistent portioning for all types

of dough. Designed for versatility, they handle a wide range

of hydration levels, making them ideal for artisanal and industrial

bakeries. With advanced engineering and a robust build, these

dividers minimise waste, enhance efficiency, and guarantee a

long service life.

Continent Dough Dividers – Key Highlights

- Semi-Industrial & Compact – Space-saving design with high performance.

- High Weight Accuracy – Ensures consistent portioning for every batch.

- Versatile Dough Handling – Suitable for a wide range of dough types.

- Adaptable Hopper Sizes – Flexibly accommodates different batch sizes.

- Easy Maintenance – Quick cleaning of all dough-contact surfaces.

- Customizable Features – Tailored to meet individual bakery needs.

- Low Machine Height – Provides maximum accessibility and ease of use.

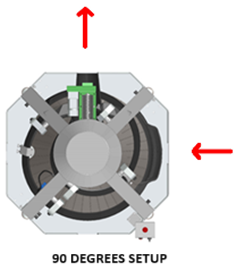

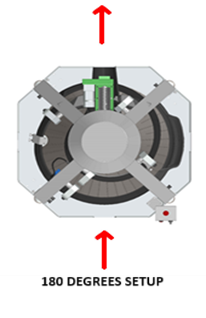

Continent Dough Dividing Process

Kreazot’s dough divider operates in a two-step process for precision and efficiency. First, a portion of the dough is estimated to be drawn into the main chamber. Then, the dividing chamber accurately measures and portions each piece to the desired weight. A 90° rotating drum gently transfers the dough onto the inner conveyor, then moves it seamlessly to the discharge conveyor. Since the dough volume in the main chamber is already close to the final portion size, the entire system ensures a smooth, consistent, and dough-friendly process, preserving quality and texture.

PRIMARY SETUP

Choice of 1, 2, or 3 pistons

Ni-Resist material for dividing chamber, main piston, measuring piston, and hopper base (resistant to wear, corrosion, and oxidation)

Cast iron crankshaft

Knife-hardened steel components

BEKA-Groeneveld brand oiling pump with 8 fixed dosing valves

Teflon-coated 160 kg drop hopper volume

Stainless steel panels encompassing the machine

Analog weight adjustment with position indicator

Analog spring pressure adjustment with position indicator

Variable speed adjustments via inverter for main cutting, main conveyor, and transport conveyor

7-liter capacity stainless steel oil reservoir

Alert for insufficient oil supply

Detachable discharge conveyor for convenient cleaning

Specify the left or right-hand side of the cross-discharge conveyor when ordering

Belt oiling mechanism

Electronic piece counter

Magnetic safety sensors

Electromechanical control panel

OPTIONS

Automatic flour duster

Custom version of discharge conveyor

Hopper oiling feature

Teflon-coated 250 kg drop hopper volume

Conveyor safeguard

Trip wire safety switch for hopper

HMI Controller

HMI Controller (with automatic weight adjustment)

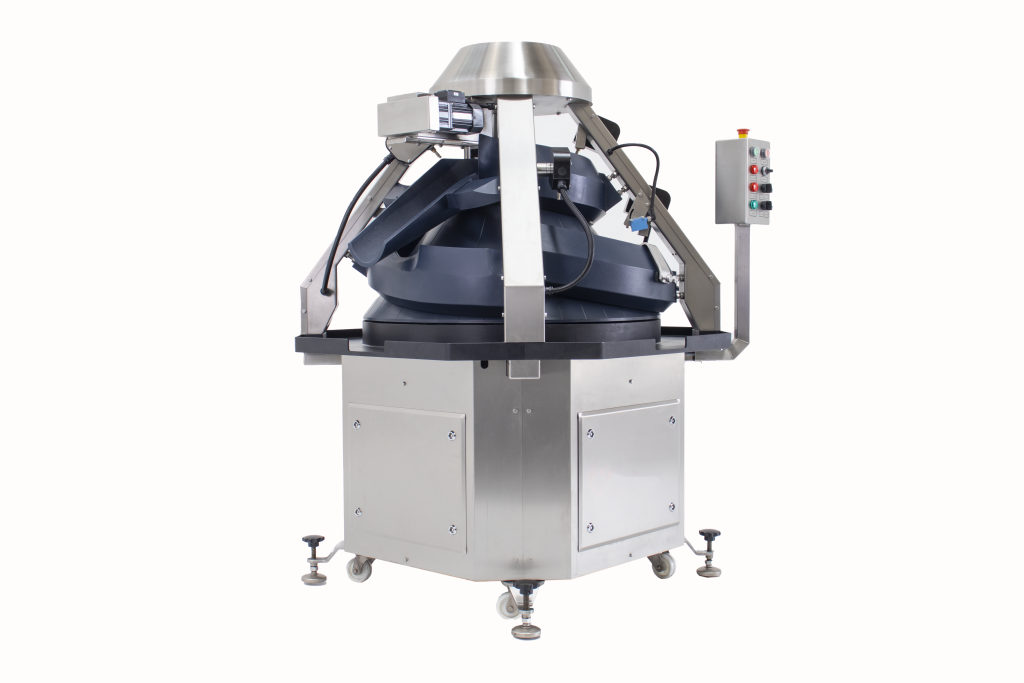

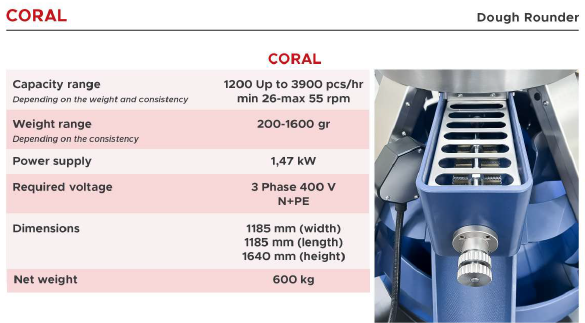

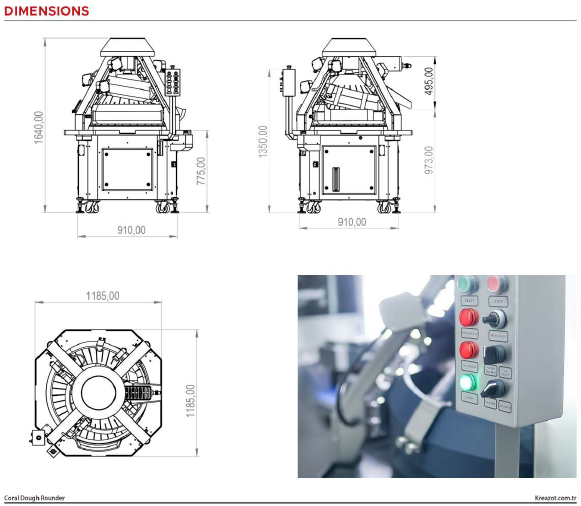

CORAL CONICAL ROUNDERS -CORAL 4100 / CORAL 3400

A highly efficient conical rounder built for durability and long service life. Its versatile design ensures consistent rounding of nearly all types of dough in virtually any bakery environment.

Coral Conical Rounders – Precision & Reliability

The Coral Conical Rounders ensure exceptional consistency and durability, delivering perfectly rounded dough pieces for a wide range of applications. Designed for versatility, they accommodate various dough types and hydration levels, making them ideal for both artisanal and industrial bakeries. With advanced engineering and a robust build, these rounders enhance efficiency, minimise dough stress, and guarantee a long service life.

Coral Conical Rounders – Key Highlights

- Precision & Consistency – Ensures uniform rounding for various dough types.

- Versatile Performance – Suitable for both artisanal and industrial bakeries.

- Gentle Dough Handling – Maintains dough structure and quality.

- Robust & Durable – Engineered for long-term reliability.

- Efficiency & Speed – Optimizes production flow with minimal waste.

Coral Conical Rounder – Working Method

The Coral Conical Rounder operates with a rotating conical drum and adjustable guiding tracks, ensuring uniform rounding of dough pieces. As the dough moves along the spiralling tracks, it naturally forms a smooth, tight surface, improving dough structure and handling. This gentle yet efficient process allows for consistent shaping while preserving dough integrity, making it ideal for various hydration levels and bakery applications.

Primary Setup

Frame and surrounding panels are entirely made of stainless steel.

Teflon-coated cast iron cone.

4.1 or 3.4 meter rounding length cast aluminium tracks, both inside and outside, Teflon-coated.

Teflon-coated cast aluminium crumb collection tray.

Teflon-coated cast aluminium outfeed chute.

Inverter-controlled speed for the cone.

Cone equipped with a top bearing.

Round head cover made of stainless steel.

Automatic flour duster.

Stainless steel swivel castors with mounting pins.

Electromechanical control panel.

Options

5 oil spraying nozzles on the cone.

Air blower with heating capability.

Option for a dough discharge conveyor in place of the chute

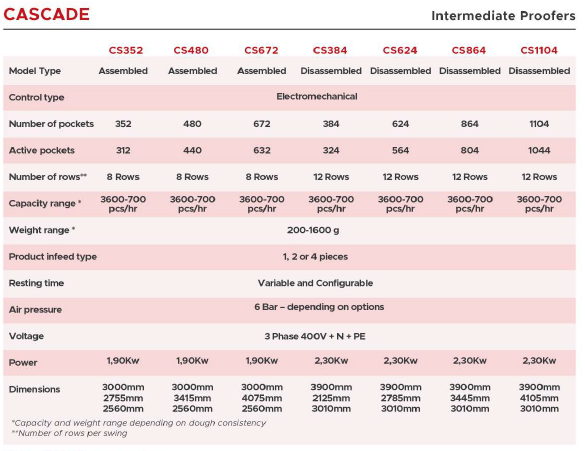

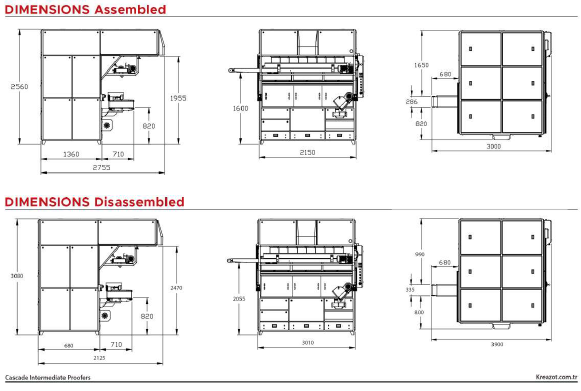

CASCADE Intermediate Proofers

8-row modulated assembled models and 12-row modulated disassembled models

This intermediate dough proofer is designed for various dough types, offering flexible proofing times and round pockets that enhance the proofing process for optimal results.

Cascade – Precision & Reliability

The Cascade intermediate proofer delivers exceptional precision and reliability. Its photocell-controlled infeed system ensures the accurate placement of dough pieces for consistent proofing. The proofer operates seamlessly in intermittent and continuous modes, offering flexibility for different production needs. Designed for durability, the ultraviolet lamps prevent mould growth, while the transparent windows allow for clear visibility, ensuring reliable monitoring of dough quality.

Cascade Intermediate Proofer – Key Highlights

- Infeed System: Powered by photocell or V-step belt

- Operation Modes: Can run intermittently or continuously

- Proofer Pockets: Round polyethylene pockets (Ø 190 mm), removable and washable

- Construction: Stainless steel frame, turning device, proofer trays, and panels

- Dough Contact Areas: Teflon-coated for smooth and efficient dough handling

- Chain & Guides: Durable stainless steel chain with integrated guides

- Drive Mechanism: SEW gearbox with shear pin protection for added reliability

- Control Panel: Integrated switchboard for easy access and control

- Discharge System: Outfeed chute located on the last row for streamlined dough removal

- The Cascade is available in assembled and disassembled models, offering flexibility for installation and transportation needs

Cascade – Working Method

The Cascade intermediate proofer operates through a controlled infeed system using either a photocell or a V-step belt, ensuring accurate placement of rounded dough pieces into the proofer pockets. These round polyethene pockets (Ø 190 mm) are designed to hold the dough pieces securely during the proofing process. The machine can run in either intermittent mode for full pocket filling or continuous mode for a steady flow of dough. As the dough moves through the proofer, the system provides the necessary environmental conditions for optimal proofing. The Teflon-coated parts in contact with the dough reduce friction and improve dough handling, while the ultraviolet lamps prevent mould formation inside the proofer. The dough pieces are then discharged via an outfeed chute on the last row, ready for the next stage of production

Primary Setup

- Stainless steel frame and swings throughout.

- Modular, unmounted system.

- Nylon-mesh round pockets, easily removable for cleaning, accommodating weights from 200 to 1,600 grams.

- Standard 8 modulated pockets on swings for all models.

- Infeed conveyor with photocell control and continuous drive.

- Flour duster on the infeed conveyor.

- Adjustable collection drawers for resting dough, allowing for the desired proofing time before the dough piece exits.

- Outfeed cross conveyor.

- Synchronized speed controller aligned with the divider.

- Electrical cabinet positioned at working height, equipped with power supply and sockets for divider, rounder, and molder.

- Air circulation fan and UV lighting.

- Flexible layout options, specifying infeed position—right or left side, front or rear—required when placing an order.

- Electromechanical control panel.

Options

Climator unit

Hot air blower

Flour duster

UV Lighting

Air circulation fan

Configuration methods

Single infeed

Single outfeed

Single infeed with a valve for dual depositing

Dual infeed

Dual outfeed

Dual infeed with valves for four depositing

Output valve

Rear infeed

OCEAN Long Molders

The OCEAN Series of long moulders is designed for artisan and industrial bakeries, offering precise shaping, gentle dough handling, and durable stainless steel construction.

Ocean M & B: Universal moulders for versatile bread types.

Ocean Advanced: Specialized for tin loaf production with automation.

Ocean Combi Series (Combi, Sharp, Flow): Industrial models with high efficiency—Sharp for tapered loaves, Flow for continuous automated production.

Together, they provide reliable solutions for everything from traditional loaves to large-scale automated bread lines.

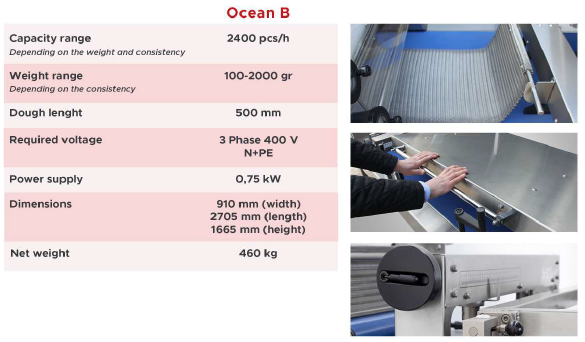

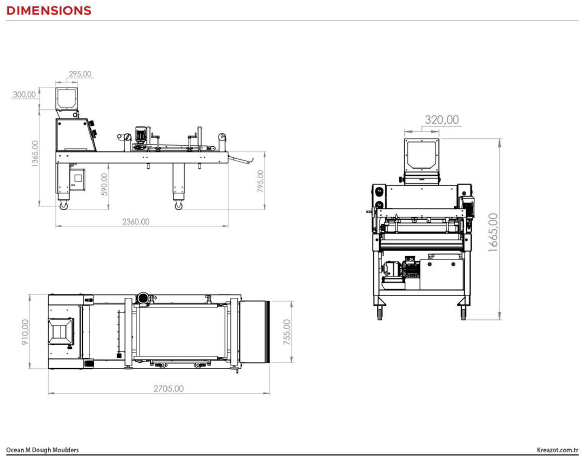

OCEAN B

A highly efficient long moulder with a proven long lifespan. Designed for versatility, it ensures uniform shaping of nearly any type of dough in almost any bakery setting.

Ocean B – Precision & Reliability

The Ocean B Model Long Moulder ensures exceptional consistency and durability, delivering perfectly moulded dough pieces for a wide range of applications. Designed for versatility, it accommodates various dough types and hydration levels, making it ideal for both artisanal and industrial bakeries. With advanced engineering and a robust build, this moulder enhances efficiency, preserves dough structure, and guarantees a long service life.

Ocean B – Key Highlights

- Precision & Consistency – Ensures uniform shaping for various dough types.

- Versatile Performance – Suitable for both artisanal and industrial bakeries.

- Adjustable Settings – Customizable pressure board and rolling system for different dough textures.

- Gentle Dough Handling – Preserves dough structure while achieving optimal shaping.

- Robust & Durable – Engineered for long-term reliability with a sturdy build.

- Efficiency & Speed – Optimises production flow while minimising waste.

- Compact & Ergonomic Design – Space-saving structure with user-friendly operation

Ocean B – Working Method

The Ocean B Model Long Moulder operates through a systematic rolling and shaping process, ensuring uniform dough elongation while preserving its structure. Dough pieces enter the moulder infeed. They pass through a set of adjustable sheeting rollers, which gently flatten the dough to the desired thickness. The dough is then guided into a curling net or belt, where it is gently rolled into a cylindrical shape. This process helps develop the dough’s structure and creates the initial shape for final moulding. The shaped dough moves under a fixed pressure board, which elongates it to the required length. The pressure board is adjustable, allowing control over the final shape and tightness of the dough. Once moulded, the dough exits the machine and is ready for further processing, such as proofing or baking. The Ocean B Model Long Moulder is designed for high precision, versatility, and gentle handling, making it ideal for a wide range of bakery applications.

Primary Setup

Robust stainless steel frame and adjacent panels

Centrally adjustable inlet hopper ensures consistent and precise

positioning of the dough piece

Dual sets of adjustable pressure rollers, equipped with position

indicators and scrapers to prevent adhesion

Stainless steel wire belt for preliminary shaping

Collection tray coated with Teflon for easy cleaning

Parallel adjustable side guides (15-30 mm) with turntable handles

Height-adjustable non-stick fixed pressure board, folded upright via a dashpot mechanism

Utilizes a clean line belt in blue color, coated with polyolefin material.

Height-adjustable wheels with brakes for convenient mobility

Options

Flour duster

Cup elevator

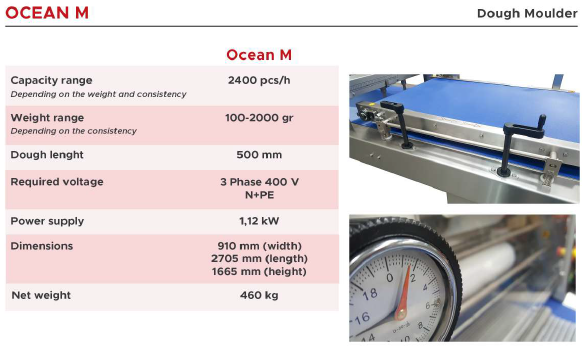

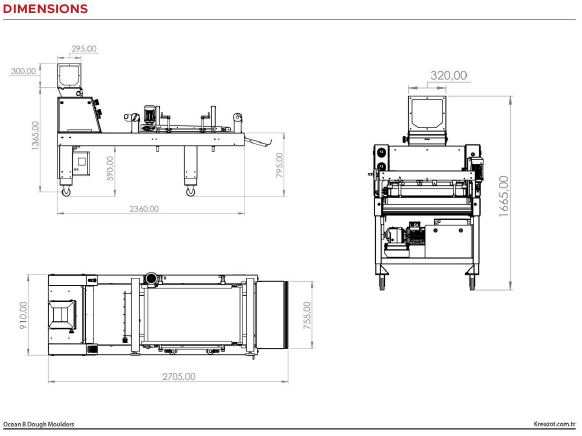

OCEAN M

A highly efficient long moulder with a proven long lifespan. Designed for versatility, it ensures uniform shaping of nearly any type of dough in almost any bakery setting.

Ocean M Long Moulder – Precision & Reliability

The Ocean M Model Long Moulder ensures exceptional consistency and durability, delivering perfectly moulded dough pieces for a wide range of applications. Designed for versatility, it accommodates various dough types and hydration levels, making it ideal for both artisanal and industrial bakeries. With advanced engineering and a robust build, this moulder enhances efficiency, preserves dough structure, and guarantees a long service life.

Ocean M Long Moulder – Key Highlights

- Precision & Consistency – Ensures uniform shaping for various dough types.

- Versatile Performance – Suitable for both artisanal and industrial bakeries.

- Adjustable Settings – Customizable motorised pressure board and rolling system for different dough textures.

- Gentle Dough Handling – Preserves dough structure while achieving optimal shaping.

- Robust & Durable – Engineered for long-term reliability with a sturdy build.

- Efficiency & Speed – Optimizes production flow while minimizing waste.

- Compact & Ergonomic Design – Space-saving structure with user-friendly operation.

.

Ocean M Long Moulder – Working Method

The Ocean M Model Long Moulder operates through a systematic rolling and shaping process, ensuring uniform dough elongation while preserving its structure. Dough pieces enter the moulder infeed. They pass through a set of adjustable sheeting rollers, gently flattening the dough to the desired thickness. The dough is then guided into a curling net or belt, where it is gently rolled into a cylindrical shape. This process helps develop the dough’s structure and creates the initial shape for final moulding. The shaped dough moves under a motorised pressure board, which elongates it to the required length. The pressure board is adjustable, allowing control over the final shape and tightness of the dough.

Primary Setup

- Entirely constructed from stainless steel, including the frame and surrounding panels.

- The centrally adjustable infeed hopper ensures consistent and precise positioning of the dough piece.

- Equipped with two sets of non-stick adjustable pressure rollers, accompanied by position indicators and scrapers to prevent adherence.

- Features a stainless steel wire belt for pre-moulding purposes.

- Includes a collection tray coated with Teflon for easy cleaning.

- parallel adjustable side guides of 15-30 mm, featuring turntable handles.

- Height-adjustable non-stick motorised pressure board, folded upright by a dashpot mechanism.

- Utilises a clean line belt in blue colour, coated with polyolefin material.

- Equipped with height-adjustable wheels featuring brakes for effortless movement

Options

Flour duster

Cup elevator

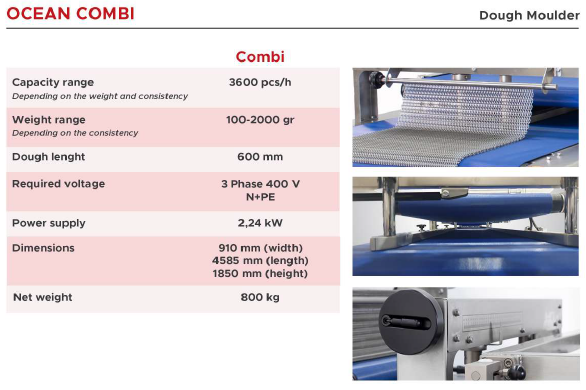

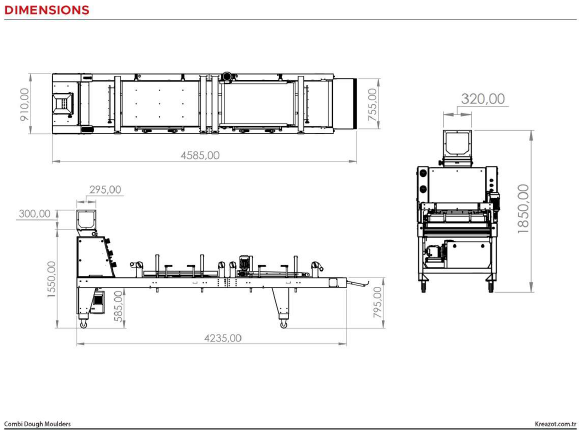

OCEAN COMBI

The Kreazot Ocean Combi is a highly efficient long-dough moulder designed for industrial bread production. Built with robust stainless steel construction, it ensures uniform shaping of various dough types, including wheat and rye blends, across diverse bakery settings. Its versatility and durability make it an ideal choice for bakers seeking consistent quality and performance.

Ocean COMBI Long Moulder – Precision & Reliability

The Ocean COMBI Long Moulder delivers exceptional precision and reliability, ensuring uniform shaping and gentle dough handling for a wide range of bread types. Engineered with advanced technology and a durable stainless steel build, it maintains dough integrity while optimizing production efficiency. Designed for both artisanal and industrial bakeries, the Ocean COMBI guarantees consistent results, minimal waste, and a long service life, making it an essential solution for high-quality bread production

Ocean COMBI Long Moulder – Key Highlights

- Versatile Dough Handling – Suitable for a wide range of dough types and hydration levels.

- Precision Moulding – Ensures uniform shaping with consistent results.

- Adjustable Sheeting & Rolling – Customizable settings for different bread varieties.

- Robust Stainless Steel Construction – Heavy-duty, hygienic, and built for long-term use.

- Gentle Dough Treatment – Preserves dough structure and prevents stress.

- High Efficiency & Productivity – Designed for continuous operation in industrial bakeries.

- Seamless Integration – Easily fits into existing production lines.

- User-Friendly Operation – Intuitive controls for quick adjustments and minimal downtime.

Ocean COMBI Long Moulder – Working Method

The Ocean COMBI Long Moulder is designed for precise shaping and gentle handling of various dough types, ensuring consistent results and high efficiency in industrial and artisanal bakery operations.

- Dough Infeed

Dough pieces are fed into the moulder either manually or automatically from the divider. The system ensures smooth and controlled feeding to prevent dough stress.

- Sheeting & Flattening

The dough passes through a set of adjustable rollers, gently flattening it to the desired thickness. The sheeting process helps develop dough structure while maintaining its integrity.

- Pre-Rolling & Curling

The flattened dough is guided through a curling mechanism, forming a tight pre-roll. This step helps achieve uniform shaping and ensures even baking.

- Final Rolling & Lengthening

The dough piece moves through the moulding belts, which further shape and elongate it to the required length. Adjustable pressure and belt speed settings allow customization based on the type of bread being produced.

- Outfeed & Transfer

The shaped dough is discharged onto a conveyor or directly into baking tins, depending on the production setup. The system ensures smooth handling to maintain product consistency and quality. With its precise engineering, adjustable settings, and high-capacity output, the Ocean COMBI Long Moulder is a reliable solution for bakeries looking to optimize their bread production while maintaining superior dough quality.

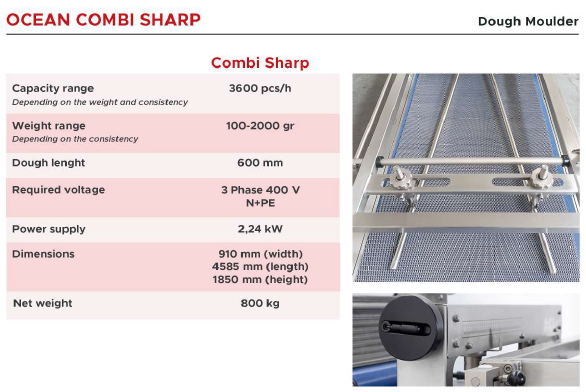

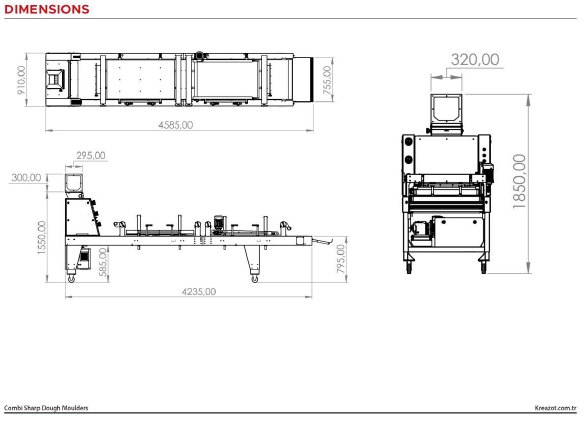

OCEAN COMBI SHARP

The Kreazot Ocean Combi Sharp is a highly efficient long-dough moulder tailored for

industrial bakery production. Constructed with robust stainless steel, it ensures uniform shaping of various dough types, including wheat and rye blends, across diverse bakery settings. Its versatility and durability make it an ideal choice for bakers seeking consistent quality and performance. Additionally, it is a specially designed machine for artisan bread production, featuring tapered edges to create the perfect traditional loaf shape while maintaining superior dough integrity.

Ocean COMBI SHARP Long Moulder – Precision & Reliability

The Ocean COMBI SHARP Long Moulder delivers exceptional precision

and reliability, ensuring uniform shaping and superior dough handling

for artisan and industrial bread production. Built with high-quality

stainless steel and engineered for efficiency, it maintains dough

Integrity minimises waste and guarantees consistent results with

every batch. With its advanced moulding technology, including

tapered edge shaping for artisan loaves, the Ocean COMBI SHARP

is the perfect solution for bakeries demanding precision, durability,

and high productivity.

Ocean COMBI SHARP Long Moulder – Key Highlights

- Consistent Shaping – Guarantees precise moulding with tapered edges for authentic artisan loaves.

- Advanced Dough Handling – Maintains dough integrity while preventing stress and overworking.

- Robust Stainless Steel Construction – Heavy-duty design for long-term durability and hygiene.

- Optimised for Artisan Production – Specially designed to shape bread with tapered edges for a traditional look.

- High Efficiency & Productivity – Engineered for continuous, high-volume operation in demanding bakery environments.

- Seamless Integration – Compatible with existing and new production lines.

- User-Friendly Operation – Intuitive controls for easy adjustments and minimal downtime.

Ocean COMBI SHARP Long Moulder – Working Method

The Ocean COMBI SHARP Long Moulder is designed for precision shaping and gentle dough handling, ensuring consistent results for both artisan and industrial bread production.

- Dough Infeed

Dough pieces are fed into the machine either manually or automatically from the divider. The feeding system ensures smooth entry without damaging the dough structure.

- Sheeting & Flattening

Adjustable rollers gently sheet the dough to the desired thickness. This step helps develop dough structure while preserving its integrity.

- Pre-Rolling & Curling

The dough passes through a curling mechanism, creating a tight and uniform pre-roll. Ensures an even crumb structure and consistent loaf formation.

- Final Rolling & Lengthening

The dough moves through final shaping belts, achieving the required length and shape.

Pressure and belt speed are fully adjustable to match production needs.

- Tapered Edge Moulding

The dough is precisely shaped with tapered edges, ideal for artisan-style bread. Adjustable moulding belts allow customisation for different bread types.

- Outfeed & Transfer

The shaped dough is smoothly discharged onto a conveyor or into baking trays. Ensures gentle handling to maintain uniformity and quality.

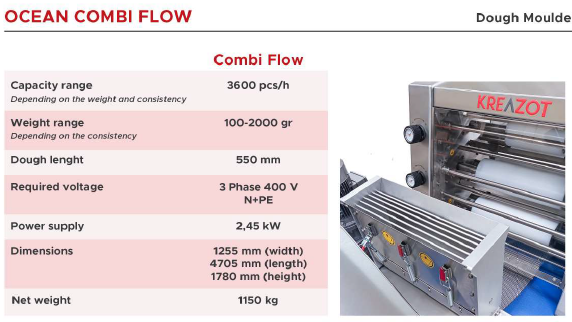

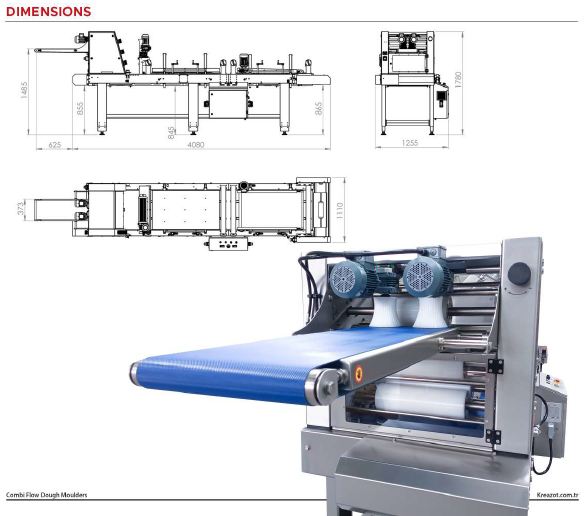

OCEAN COMBI FLOW

The OCEAN COMBI FLOW is a highly efficient long-dough moulder designed for industrial bread production. Built with robust stainless steel construction, it ensures uniform shaping of various dough types, including wheat and rye blends,

across diverse bakery settings. Its versatility

and durability make it an ideal choice for

bakers seeking automation, consistent quality and performance.

Ocean COMBI FLOW Long Moulder – Precision & Reliability

The Ocean COMBI FLOW Long Moulder delivers exceptional precision and reliability, ensuring uniform shaping and gentle dough handling for a wide range of bread types. Engineered with advanced technology and a durable stainless steel build, it maintains dough integrity while optimising production efficiency. Designed for both artisanal and industrial bakeries, the Ocean COMBI FLOW guarantees consistent results, minimal waste, and a long service life, making it an essential solution for high-quality bread production seeking automated equipment.

Ocean COMBI FLOW Long Moulder – Key Highlights

- Versatile Dough Handling – Suitable for various dough types and hydration levels.

- Precision Moulding – Ensures uniform shaping with consistent results.

- Automatic Valve for Bread Panning: Equipped with an automatic valve to ensure precise and efficient panning of bread, optimizing workflow and reducing manual labour.

- Adjustable Sheeting & Rolling – Customizable settings for different bread varieties.

- Robust Stainless Steel Construction – Heavy-duty, hygienic, and built for long-term use.

- Gentle Dough Treatment – Preserves dough structure and prevents stress.

- High Efficiency & Productivity – Designed for continuous operation in industrial bakeries.

- Seamless Integration – Easily fits into existing production lines.

- User-Friendly Operation – Intuitive controls for quick adjustments and minimal downtime.

Ocean COMBI FLOW Long Moulder – Working Method

The Ocean COMBI FLOW Long Moulder is designed for precise shaping and gentle handling of various dough types, ensuring consistent results and high efficiency in industrial and artisanal bakery operations.

- Dough Infeed

Dough pieces are fed into the moulder either manually or automatically from the divider. The system ensures smooth and controlled feeding to prevent dough stress.

- Sheeting & Flattening

The dough passes through a set of adjustable rollers, gently flattening it to the desired thickness. The sheeting process helps develop dough structure while maintaining its integrity.

- Pre-Rolling & Curling

The flattened dough is guided through a curling mechanism, forming a tight pre-roll. This step helps achieve uniform shaping and ensures even baking.

- Final Rolling & Lengthening

The dough piece moves through the moulding belts, which further shape and elongate it to the required length. Adjustable pressure and belt speed settings allow customisation based on the type of bread being produced.

- Outfeed & Transfer

The shaped dough is discharged into baking tins. The system ensures smooth handling to maintain product consistency and quality. With its precise engineering, adjustable settings, and high-capacity output, the Ocean COMBI FLOW Long Moulder is a reliable solution for bakeries looking to optimize their bread production while maintaining superior dough quality.

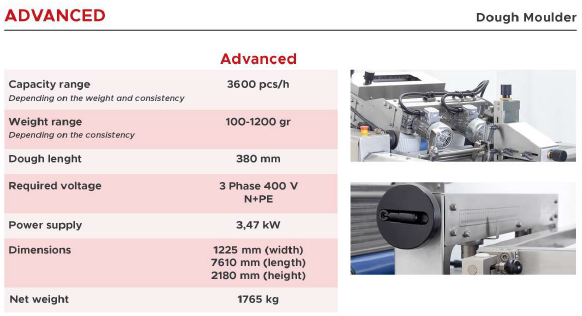

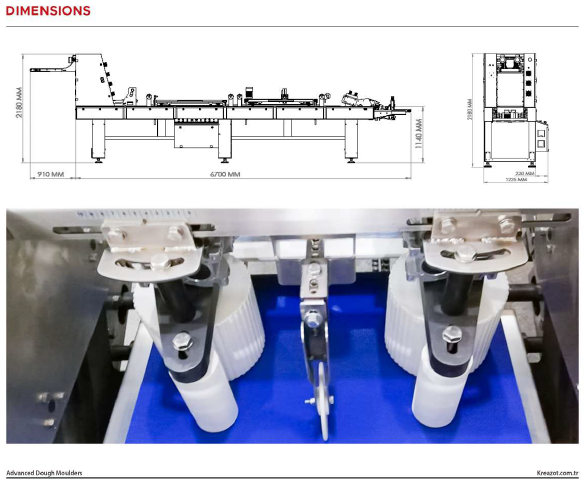

OCEAN ADVANCED

The Kreazot Advanced Long Moulder is engineered for precision and efficiency in industrial bakery production. Constructed with robust stainless steel, it ensures durability and consistent performance across various dough types. This versatile machine is ideal for bakers seeking uniform shaping and high-quality results. Specially designed for tin bread production, it provides consistent and professional shaping for tin loaves, while maintaining superior dough integrity throughout the process.

Ocean ADVANCED Long Moulder – Precision & Reliability

The Ocean ADVANCED Long Moulder is engineered for precision and reliability in industrial bakery production. Constructed with robust stainless steel, it ensures durability and consistent performance across various dough types. This versatile machine is ideal for bakers seeking uniform shaping and high-quality results. Designed specifically for tin bread production, the Ocean ADVANCED provides consistent and professional shaping for tin loaves, while maintaining superior dough integrity throughout the process.

Ocean ADVANCED Long Moulder – Key Highlights

- Precision Engineering – Guarantees consistent shaping, including special designs for tin bread production.

- Superior Durability – Built with high-quality stainless steel for long-lasting performance.

- Versatile Design – Suitable for a wide range of dough types, including wheat and rye blends.

- Gentle Dough Handling – Maintains dough integrity while minimizing stress.

- High Efficiency – Streamlined for continuous operation, delivering consistent, high-quality results.

- Customizable Settings – Adjustable features to meet diverse production needs.

- Automatic Panning Station – Integrated feature for effortless loading of shaped dough into baking trays, enhancing efficiency and ensuring consistent dough placement

Ocean ADVANCED Long Moulder – Working Method

The Ocean ADVANCED Long Moulder is designed for precision shaping and efficient dough handling, making it ideal for industrial tin bread production.

- Dough Infeed: The divided dough pieces are gently fed into the moulder, ensuring smooth and uniform processing.

- Pre-Moulding Stage: The dough is lightly compressed to prepare it for final shaping, maintaining its structure and minimising stress.

- Shaping Process: The dough passes through adjustable rollers and moulding belts, achieving the desired length and shape with consistent tension.

- Automatic Panning Station: The shaped dough is seamlessly transferred into baking tins, optimizing production flow and reducing manual handling. Continuous Operation: The system runs efficiently and reliably, integrating smoothly into high-capacity bakery lines with minimal downtime.

COMMERCIAL BAKERY EQUIPMENT

PATISSERIE OVENS

FUOCO

4 Tray Patisserie Oven (Electric)

Patisserie Oven Series

General Features

• Equal heat distribution with a bidirectional fan

• Adjustable cooking temperature between 0-300 °C

• 230 °C limit safety thermostat

• Manual humidification feature

• Automatic fan stops when the door is opened due to the magnetic switch

• Tempered glass with silicone gasket

• Stainless steel body

CAVENO

4 Tray Patisserie Oven (Electric)

Patisserie Oven Series

General Features

• Control panel with digital temperature display.

• 3-Step Cooking Function.

• Multi-step cooking feature

• High capacity program memory

• Engine speed control

• Automatic humidification feature

• Equal heat distribution with bidirectional fan

• Adjustable cooking temperature between 0-300 °C

• 230 °C limit safety thermostat

• Manual humidification feature

• Automatic fan stops when the door is opened due to the magnetic switch

• Tempered glass with silicone gasket

• Openable inner glass for easy cleaning

• Stainless steel body

MIGLIORE

4-6 Trays Patisserie Oven with Side Opening (Electric)

Patisserie Oven Series

General Features

• Control panel with digital temperature display.

• 3-Step Cooking Function.

• Multi-step cooking feature

• High capacity program memory

• Engine speed control

• Automatic humidification feature

• Equal heat distribution with bidirectional fan

• Adjustable cooking temperature between 0-300 °C

• 230 °C limit safety thermostat

• Manual humidification feature

• Automatic fan stops when the door is opened due to the magnetic switch

• Tempered glass with silicone gasket

• Openable inner glass for easy cleaning

• Stainless steel body

PEREGRIN

6 Tray Patisserie Oven (Electric – Ng)

Patisserie Oven Series

General Features

• 7” TFT Capacitive color touch screen control panel

• High capacity program memory

• Picture recipe feature

• Multi-language option

• Multi-step cooking feature

• Automatic humidification feature

• Ability to work with NG or Electric

• Equal heat distribution with bidirectional fan

• Adjustable cooking temperature between 0-300 °C

• 230 °C limit safety thermostat

• Adjustable cooking time and digital temperature display

• Manual humidification feature

• Door system with sensors

• Tempered glass with silicone gasket

• Openable inner glass for easy cleaning

• Stainless steel body

ELROND

9 Tray Patisserie Oven (Electric – Ng)

Patisserie Oven Series

General Features

• 7” TFT Capacitive color touch screen control panel

• High capacity program memory

• Picture recipe feature

• Multi-language option

• Multi-step cooking feature

• Automatic humidification feature

• Ability to work with NG or Electric

• Equal heat distribution with bidirectional fan

• Adjustable cooking temperature between 0-300 °C

• 230 °C limit safety thermostat

• Adjustable cooking time and digital temperature display

• Manual humidification feature

• Door system with sensors

• Tempered glass with silicone gasket

• Openable inner glass for easy cleaning

• Stainless steel body

VENARDI

10 Rotary Patisserie Oven (Electric – Ng)

Patisserie Oven Series

General Features

• 7” TFT Capacitive color touch screen control panel

• High capacity program memory

• Picture recipe feature

• Multi-language option

• Multi-step cooking feature

• Bidirectional rotating tray kit feature

• Ability to work with Ng or Electric

• Equal heat distribution with bidirectional fan

• Adjustable cooking temperature between 0-300 °C

• 230 °C limit safety thermostat

• Adjustable cooking time

• Manual or automatic humidification feature

• Door system with sensors

• Tempered glass with silicone gasket

• Openable inner glass for easy cleaning

• Stainless steel body

RANEVOR

Combi Oven Rotary (Electric – Ng)

Patisserie Oven Series

General Features

• 7” TFT Capacitive color touch screen control panel

• High capacity program memory

• Picture recipe feature

• Multi-language option

• Multi-step cooking feature

• Bidirectional rotating tray kit feature

• Ability to work with Ng or Electric

• Equal heat distribution with bidirectional fan

• Adjustable cooking temperature between 0-300 °C

• 230 °C limit safety thermostat

• Adjustable cooking time and digital display

• Manual or automatic humidification feature

• Door system with sensors

• Tempered glass with silicone gasket

• Openable inner glass for easy cleaning

• Stainless steel body

Combine Oven Stone Base General

ROBLIN

14 Rotary Patisserie Oven (Electric – Ng)

Patisserie Oven Series

General Features

• 7” TFT Capacitive colour touch screen control panel

• High-capacity program memory

• Picture recipe feature

• Multi-language option

• Multi-step cooking feature

• Bidirectional rotating tray kit feature

• Ability to work with Ng or Electric

• Equal heat distribution with bidirectional fan

• Adjustable cooking temperature between 0-300 °C

• 230 °C limit safety thermostat

• Adjustable cooking time

• Manual or automatic humidification feature

• Door system with sensors

• Tempered glass with silicone gasket

• Openable inner glass for easy cleaning

• Stainless steel body

IMPASTO

Fermentation Cabinet (Electric)

Patisserie Oven Series

General Features

• 0/90 C working temperature

• Steam resistance

• Digital control panel

• Digital adjustable temperature indicator

• Digital adjustable humidity indicator

• Stainless steel body

CONVECTION OVENS

BALDER

6 Tray Convection Oven (Electric – Ng)

Convection Oven Series

General Features

• 7” color LCD touch screen control panel

• High capacity program memory

• Picture recipe feature

• Multi-language option

• Multi-step cooking feature

• Automatic humidification feature

• Ability to work with Ng or Electric

• Equal heat distribution with bidirectional fan

• Adjustable cooking temperature between 0-300 °C

• 230 °C limit safety thermostat

• Adjustable cooking time and digital temperature display

• Manual humidification feature

• Door system with sensors

• Tempered glass with silicone gasket

• Openable inner glass for easy cleaning

• Stainless steel body

FREYA

10 Tray Convection Oven (Electric – Ng)

Convection Oven Series

General Features

• 7” color LCD touch screen control panel

• High capacity program memory

• Picture recipe feature

• Multi-language option

• Multi-step cooking feature

• Automatic humidification feature

• Ability to work with Ng or Electric

• Equal heat distribution with bidirectional fan

• Adjustable cooking temperature between 0-300 °C

• 230 °C limit safety thermostat

• Adjustable cooking time and digital temperature display

• Manual humidification feature

• Door system with sensors

• Tempered glass with silicone gasket

• Openable inner glass for easy cleaning

• Stainless steel body

GERDA

20 Tray Convection Oven (Electric – Ng)

Convection Oven Series

General Features

• 7” colour LCD touch screen control panel

• High capacity program memory

• Picture recipe feature

• Multi-language option

• Multi-step cooking feature

• Automatic humidification feature

• Ability to work with Ng or Electric

• Equal heat distribution with bidirectional fan

• Adjustable cooking temperature between 0-300 °C

• 230 °C limit safety thermostat

• Adjustable cooking time and digital temperature display

• Manual humidification feature

• Door system with sensors

• Tempered glass with silicone gasket

• Openable inner glass for easy cleaning

• Stainless steel body

ROCCIA

20 Tray Vertical Convection Oven (Electric – Ng)

Convection Oven Series

General Features

• 7” color LCD touch screen control panel

• High capacity program memory

• Picture recipe feature

• Multi-language option

• Multi-step cooking feature

• Automatic humidification feature

• Ability to work with Ng or Electric

• Equal heat distribution with bidirectional fan

• Adjustable cooking temperature between 0-300 °C

• 230 °C limit safety thermostat

• Adjustable cooking time and digital temperature display

• Manual humidification feature

• Door system with sensors

• Tempered glass with silicone gasket

• Openable inner glass for easy cleaning

• Stainless steel body

LOFRI

40 Tray Convection Oven (Electric – Ng)

Convection Oven Series

General Features

• 7” colour LCD touch screen control panel

• High-capacity program memory

• Picture recipe feature

• Multi-language option

• Multi-step cooking feature

• Automatic humidification feature

• Ability to work with Ng or Electric

• Equal heat distribution with bidirectional fan

• Adjustable cooking temperature between 0-300 °C

• 230 °C limit safety thermostat

• Adjustable cooking time and digital temperature display

• Manual humidification feature

• Door system with sensors

• Tempered glass with silicone gasket

• Openable inner glass for easy cleaning

• Stainless steel body

PIZZA OVENS

VEZZOLA

Electric Pizza Oven (Single Deck)

Pizza Oven Series

General Features

• Independent adjustable (maximum 400 °C) thermostat system for each deck

• Refractory baking stone

• Large glass cover system working with weight mechanism

• Isolation system that minimizes heat loss

• Separate lamp for each deck

• Manual temperature indicator for each deck

FRIGGA

Electric Pizza Oven (Double Deck)

Pizza Oven Series

General Features

• Independent adjustable (maximum 400 °C) thermostat system for each deck

• Refractory baking stone

• Large glass cover system working with weight mechanism

• Isolation system that minimizes heat loss inside the boiler

• Separate lamp for each deck

• Manual temperature indicator for each deck

PIZZARO

Gas Pizza Oven (Single Deck)

Pizza Oven Series

General Features

• Independent adjustable (maximum 400 °C) thermostat system for each deck

• Ability to work with LPG or NG

• Manual thermostat control

• Electronic ignition system

• Continuous flame control

• Refractory baking stone

DREAY

Gas Pizza Oven Deck (Double Deck)

Pizza Oven Series

General Features

• Independent adjustable (maximum 400 °C) thermostat system for each deck

• Ability to work with LPG or NG

• Manual thermostat control

• Electronic ignition system

• Continuous flame control

• Refractory baking stone

TALBOT

Electric Pizza Oven Bottom Stands

Pizza Oven Bottom Stands

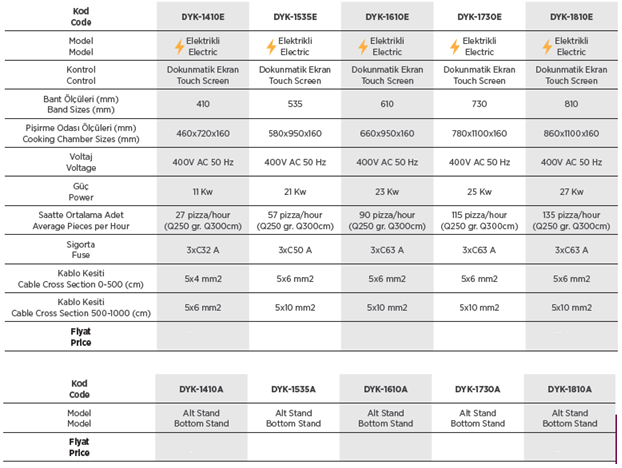

CONVEYOR PIZZA OVEN

ANNATOLI

Conveyor Pizza Oven (Electric)

Conveyor Pizza Oven Series

General Features

• Stainless steel body

• Low power consumption and product-focused system provides homogeneous cooking

• LCD touch screen for easy use

• Cooking time is 1-30 minutes

• Saving time with fast and efficient working

• Double Deck-sided rotating belt system

• Temperature can be adjusted between 0-400 °C

• Low energy consumption

GUSTO

Conveyor Pizza Oven (NG)

Conveyor Pizza Oven Series

General Features

• Stainless steel body

• Low gas consumption and product-focused system provides homogeneous cooking

• LCD touch screen for easy use

• Cooking time is 1-30 minutes

• Saving time with fast and efficient working

• Double Deck-sided rotating belt system

• Temperature can be adjusted between 0-400 °C

• Low energy consumption

DOME PIZZA OVENS

VESPERO

Stone-Based Electric Pizza Oven

Dome Pizza Oven Series

General Features

• 600×600 mm and 700×700 mm cooking stone.

• 280 mm oven inner height

• 350x190mm door dimension

• Adjustable cooking temperature and manual

display from 0 ° C to 400 ° C

• Stainless Steel Inner Chambe

NATELLO

Stone-Based Pizza Oven (Gas)

Dome Pizza Oven Series

General Features

• Adjustable cooking temperature between 0-300 °C

• 600×600 mm and 700x700mm cooking stone

• 430mm oven inner height

• 350x190mm door dimension

• Ability to work with NG or LPG

• Control with piezzo lighter

• Manual inner temperature display

• Safety valve taps

• Stone inner dome compartment

LEONAR

Stone-Based Wood Pizza Oven

Dome Pizza Oven Series

General Features

• 600×600 mm and 700x700mm cooking stone

• 430mm oven inner height

• 350x190mm door dimension

• Manual inner temperature display

• Stone inner dome compartment

GIORNO

Stone-Based Wood Pizza Oven

Dome Pizza Oven Series

General Features

• 1250×1250 mm and 1500×1500 mm cooking stone

• 500 mm oven inner height

• 500×210 mm door dimension

• Manual inner temperature display

• Stone inner dome compartment

GALADRI

Rotary Base Electric Pizza Oven

Dome Pizza Oven Series

General Features

• 7 ” Colour Touch Control Panel

• Adjustable temperature from the display

• Adjustable table speed (0-10) from the screen

• Upper temperature set value and upper temperature display

• Lower temperature set value and lower temperature display

• Maximum upper and lower temperature determination

• Minimum lower and upper temperature determination

• Adjustable cooking temperature and digital display from 0 ° C to 400 ° C

• 450 ° C limit thermostat

• 220 V. 50/60 Hz. Working Power

• 225 mm oven inner height

• 500×215 mm door size

• Thermal fixing facility that provides fast and efficient cooking

• Thermostatic heating

• Rotating base for homogeneous cooking

• Refractor Cooking Stone

• Stainless Steel Inner Chamber

RAVENNA

Foldable Electric Pizza Oven

Dome Pizza Oven Series

General Features

• 7 ”Color Touch Control Panel

• Adjustable temperature from the display

• Adjustable table speed (0-10) from the screen

• Upper temperature set value and upper temperature display

• Lower temperature set value and lower temperature display

• Maximum upper and lower temperature determination

• Minimum lower and upper temperature determination

• Adjustable cooking temperature and digital display from 0 ° C to 400 ° C

• 450 ° C limit thermostat

• 380 V. 50/60 Hz. Working Power

• 225 mm oven inner height

• 575×225 mm door size

• Thermal fixing facility that provides fast and efficient cooking.

• Thermostatic heating

• Rotating base for homogeneous cooking

• Refractor Cooking Stone

• Stainless Steel Inner Chamber

FIAMMA

Fixed Base Gas Pizza Oven

Dome Pizza Oven Series

General Features

• 7 ” Colour Touch Control Panel

• Adjustable flame length (0-10) from the screen

• Adjustable set temperature value

• Adjustable cooking temperature and digital display from 0 °C to 400 ° C

• 450 ° C limit thermostat

• 220 V. 50/60 Hz. Working Power

• Ability to work with LPG and NG

• 450 mm oven inner height

• 500×215 mm door size

• Refractor Cooking Stone

• Stone Dome Inner compartment

MAESTRO

Rotary Base Gas Pizza Oven

Dome Pizza Oven Series

General Features

• 7 ” Colour Touch Control Panel

• Adjustable flame length (0-10) from the screen

• Adjustable table speed (0-10) from the screen

• Adjustable set temperature value

• Adjustable cooking temperature and digital display from 0 °C to 400 ° C

• 450 ° C limit thermostat

• 220 V. 50/60 Hz. Working Power

• Ability to work with LPG and NG

• 450 mm oven inner height

• 500×215 mm door size

• Refractor Cooking Stone

• Stone Dome Inner compartment

MODULAR OVEN SERIES

DWALIN

Bakery Products and Sweet Pastry Oven Electric (Mini)

Modular Oven Series

General Features

• 7” TFT Capacitive colour touch screen control panel

• High capacity program memory

• Picture recipe feature

• Multi-language option

• Adjustable lower and upper heat temperatures

• 300 °C adjustable cooking temperature

• Automatic working feature with real time clock

• Manual or automatic humidification feature

• Ability to operate each floor independently

• It can be made in one, two or three deck upon request

• Equal heat distribution

DORI

Bakery Products and Sweet Pastries Oven Electric

Modular Oven Series

General Features

• 7” TFT Capacitive color touch screen control panel

• High capacity program memory

• Picture recipe feature

• Multi-language option

• Adjustable lower and upper heat temperatures

• 300 °C adjustable cooking temperature

• Automatic working feature with real time clock

• Manual or automatic humidification feature

• Ability to operate each deck independently

• It can be made in one, two or three deck upon request

• Equal heat distribution

PIZZA, PIDE & PITA BREAD OVEN SERIES

ALONAR

Pizza, Pide & Pita Oven Ng

Pizza, Pide Oven Series

General Features

• It works with a safety valve tap system

• Ability to operate at 0 °C – 400 °C temperature

• 250x250x30 mm stone baking base

• The upper part is fully isolated

• Ovens are with wheels, they can be easily moved to the desired place due to the wheels

• Ovens have 2 or 3 burners at the bottom and 2 burners at the top

• Ability to work with Ng – LPG

• Upper and lower burners operate independently of each other

RADAGAST

Pide and Turkish Pizza Oven

Pizza, Pide & Oven Series

General Features

• It works with a safety valve tap system

• Ability to operate at 0 °C – 350 °C temperature

• 250x250x30 mm stone baking base

• The upper part is fully isolated

• Equipped with wheels, the ovens can be effortlessly relocated to any desired position.

• Ovens have 2 or 3 burners at the bottom and 2 burners at the top

• Ability to work with Ng – LPG

• Upper and lower burners operate independently of each other.

• Tiles are used in ovens and can be made in the desired

colour (Special tiles are not included in the price)

COMMERCIAL DOUGH PREPARATION AND HANDLING EQUIPMENT

SPIRAL MIXERS WITH FIXED BOWL

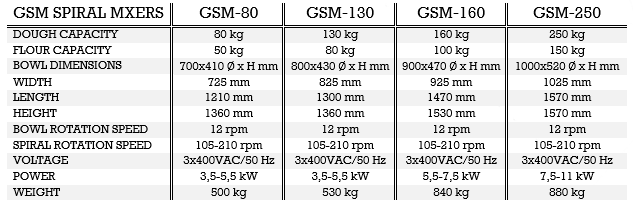

ECYAD Spiral Mixers with fixed bowls have been designed to gently mix a wide variety of doughs and are available in four different capacities and sizes.

Spirals, arms, and bowls are manufactured from high-grade hygienic stainless steel, ensuring maximum durability, easy cleaning, and full compliance with food safety standards.

Each mixer is fitted with a safety guard to confirm to the strictest safety requirements.

The customer has the choice of 4 models with a capacity ranging from 80 kg to 250 kg, bowl, dividing blade and spiral arm engineered in hygienic stainless steel for quick cleaning.

Independent motors for both the spiral arm and bowl. Simple to use manual control 38 panel with automatic or manual working cycles (two speeds – two timers), ABS thermo foamed head cover, locking safety castors for effortless positioning and genuine stability.

SELF-TILTING SPIRAL MIXERS

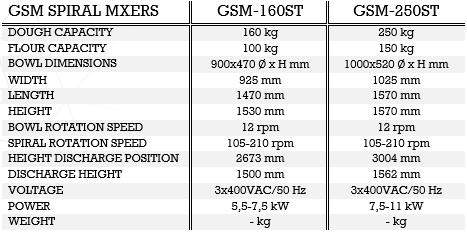

Self-tilting spiral mixer are engineered for professional bakeries, combining efficiency, safety, and hygiene.

The spiral, mixing arm, and bowl are made entirely of stainless steel for durability and food safety compliance. Its self-tilting bowl allows effortless dough discharge, while the integrated hydraulic lifting unit ensures smooth handling. Independently adjustable low- and high-speed timers provide precise mixing, and the monoblock construction with 16-channel pulley belt transmission guarantees vibration-free, low-noise operation.

The mixer can operate automatically or manually, and the bowl rotates in both directions for uniform dough development. A safety switch on the bowl lid and optional metal or ABS lid enhance operator safety, while mixing time is reduced by up to 50% compared to conventional mixers.

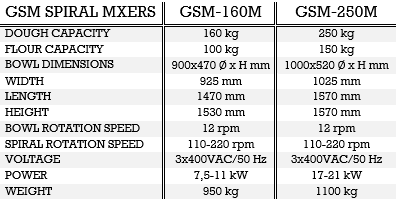

SPIRAL MIXERS WITH WHEEL-OUT BOWL

The new removable bowl industrial mixer has been enhanced with features designed to make the mixing process as simple and efficient as possible. The stainless-steel bowl can be easily removed thanks to the ergonomically positioned handle and bowl guide rollers. It also comes with a stainless-steel bowl lid to minimise flour dust emissions.

A perfectly shaped stainless steel spiral arm gently rotates along the side of the bowl to create perfectly soft dough. The customer has the choice of 2 models 160kg and 250kg.

Bowl, dividing blade and spiral arm engineered in hygienic stainless steel for quick and easy cleaning. Interchangeable trolley with ergonomically positioned handle.

Features an innovative user-friendly controller with independent motors for both the bowl and spiral arm. Stainless steel safety grid to conform to the strictest safety requirements. Dual digital time for exact mixing.

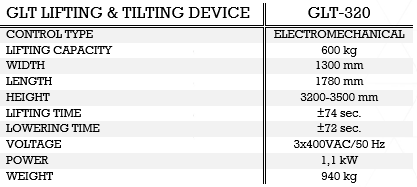

LIFTING & TILTING DEVICE

The bowl lifter and unloader, available in two models, provides practical and reliable solutions for lifting both small and large quantities of dough. Dough can be unloaded onto work tables or volumetric dividers, either individually or integrated into automatic production lines.

Its robust steel structure ensures excellent stability and durability, while the mechanical lifting mechanism operates quickly, quietly, and safely. This model features adjustable heights with unloading on both sides, and the lifters can be paired with various types of bowls for maximum versatility.